BOROUGE COMPLEX EXPANSION AND DEVELOPMENT

PROJECT This project underscores Tecnimont's expertise in managing large-scale petrochemical projects across diverse geographical locations, from Milan to Abu Dhabi, and showcases their commitment to operational excellence and innovation.Total installed capacity since 1999

Height of loop reactors integral to Borouge's processing capability

Borouge is a joint venture between the Abu Dhabi National Oil Company (ADNOC), one of the world's largest oil and gas companies, and Borealis, an Austrian leading international producer of chemical and plastic solutions.

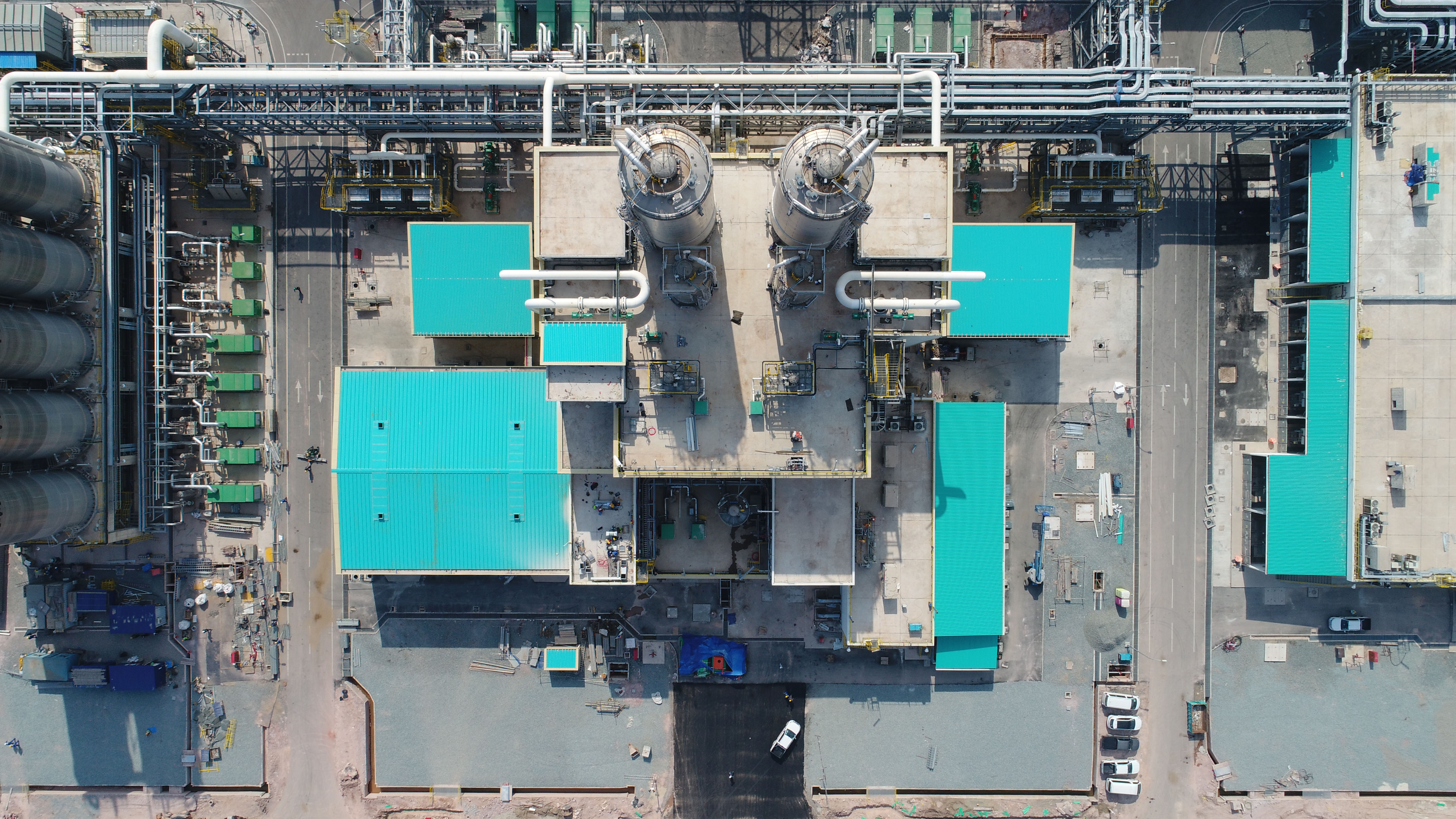

Borouge in Arabic means “tower” such as those 70 m high supporting the loop reactors, the beating heart of the plant, which transform crude oil derivates into impressive quantities of plastic, used today in many advanced industrial applications.

The Borouge project has had a profound impact on Abu Dhabi's economy and industrial landscape. By continually expanding its production capabilities, Borouge has created numerous job opportunities, both directly and indirectly, contributing to the socio-economic development of the region. The project has also facilitated technology transfer and skill development, enhancing the local workforce's expertise.

For ADNOC and Borealis, the project has strengthened their market presence, enabling them to meet the increasing global demand for high-performance plastics. The use of Borealis' Borstar technology has ensured that the products are of the highest quality, meeting stringent international standards.

Moreover, the Borouge expansions have supported the UAE's vision of economic diversification, reducing its reliance on crude oil exports by transforming oil derivatives into valuable petrochemical products. This strategic move aligns with the nation's long-term economic goals and sustainability initiatives.

The project has been developed in multiple operating centers located in different areas of the globe: Milan, Malta, Seoul, Mumbai, Salzgitter, Abu Dhabi and Ruwais.

The construction site sandy environment (the first time in the world for an LDPE plant) required specific attention to cleanliness of materials, demanding a total absence of impurities. With the provided high-pressure technology, the process liquids reach pressure levels of 3,000 atmospheres, demanding the highest standards of quality and safety.

TECNIMONT'S INVOLVEMENT IN THE BOROUGE PROJECT OVER THE DECADES HAS BEEN A CORNERSTONE OF ABU DHABI'S INDUSTRIAL GROWTH, DRIVING TECHNOLOGICAL ADVANCEMENTS, ECONOMIC DEVELOPMENT, AND GLOBAL MARKET INTEGRATION.

Borouge 1

Initiated in 2001, Borouge 1 marked the foundation with the establishment of two polyethylene units (PE1 and PE2), each with a capacity of 250,000 tons per year. This phase was crucial for setting up the initial infrastructure and production capabilities, providing a base for future expansions.

BOROUGE 1 EPC: PE1 250,000 t/y and PE2 250,000 t/y (2001)

BOROUGE 1 Revamping FEED+EPC: PE1 to 320,000 t/y (2005)

BOROUGE 1 Revamping EPC: PE2 to 280,000 t/y (2009)

Borouge 2

In 2010, the Borouge 2 expansion project introduced substantial additions, including PE3 with a capacity of 540,000 tons per year and two polypropylene units (PP1 and PP2), each producing 400,000 tons per year. This phase significantly boosted the production capacity, allowing Borouge to meet the growing global demand for polyolefins and enhance its market presence.

BOROUGE 2 Expansion Project EPC: PE3 540,000 t/y, PP1 400,000 t/y and PP2 400,000 t/y (2010)

BOROUGE 1 and BOROUGE 2 Revamping EPC: Change in Supply Chain (2013)

Borouge 3

The most extensive phase before the latest, Borouge 3, completed in 2015, saw the addition of PE4 and PE5, each with a capacity of 540,000 tons per year, along with PP3 (480,000 t/y), PP4 (428,000 t/y), and LDPE (350,000 t/y). This expansion included state-of-the-art technology and extensive infrastructure enhancements, positioning Borouge as a leader in the petrochemical industry.

BOROUGE 3 PDP: LDPE 350,000 t/y (2009)

BOROUGE 3 FEED: PE4 540,000 t/y, PE5 540,000 t/y, PP3 480,000 t/y, PP4 428,000 t/y, LDPE 350,000 t/y, 1-Butene 28,000 t/y + U&O (2010)

BOROUGE 3 EPC: PE4 540,000 t/y, PE5 540,000 t/y, PP3 480,000 t/y, PP4 428,000 t/y, LDPE 350,000 t/y (2015)

BOROUGE 3 FEED + CE: PP5 480,000 t/y (2015)

BOROUGE 3 EPs: PP5 Tie-In Works (2018)

BOROUGE 3 EPC: PP5 480,000 t/y (additional unit integrated in Borouge 3)

Borouge 4

Currently underway, Borouge 4 represents a significant leap forward with an investment of USD 3.5 billion. This phase will add new polyolefin units and cross-linkable polyethylene facilities, alongside essential utilities and offsite infrastructure: the “polyolefin units package”, which includes two polyethylene units with a capacity of 700,000 tons per year each, and 1-hexene unit, the “cross-linkable polyethylene unit package”, the “utilities and offsites package”, which includes the utilities and offsites units for the whole Borouge 4 project.

The project’s scope of work entails complete engineering services, equipment and material supply, erection and construction activities, commissioning and start up assistance.

The completion in expected by 2025. Once the project is completed, the Ruwais complex will be the world’s largest single-site polyolefin facility.

DISCOVER OTHER PROJECTS

Get to know us and how we work by browsing through our current and past projects.